Reducing CO2 emissions through the use of "solvent free" adhesives.

Now more than ever, the issue of global warming and CO2 emissions is at the center of the global debate.

It is since 2007 that Secad has chosen to implement its production capacity with a system that would not contribute to the increase in CO2 emissions. At least not in a direct way, since the electricity used is certainly still largely produced with non-green technologies!

It has in fact chosen to set up a plant for the coating of UV-crosslinkable acrylic adhesives characterised by the total absence of solvents or other volatile elements.

In fact, there remains the big issue of electricity production, which will be increasingly in demand in the future as the number of electric cars increases. And it will have to be increasingly clean!

Solvent adhesives have the characteristic of being composed of a resin dispersed in one or more solvents. As a rule, hexane (C6H14) and ethyl acetate (CH3COOC2H5) are the most frequently found. Given the inability of many production sites to recover the solvent used, these are burned through combustion using an afterburner. Within an afterburner, VOCs (Volatile Organic Compounds), a category of compounds including aliphatic hydrocarbons, aromatics, aldehydes, alcohols and ketones, are removed. And it is during this process that the formation of CO2 occurs. Taking the two solvents mentioned above as a reference, the combustion reactions are:

2 C6H14 + 19 O2 –> 12 CO2 + 14 H2O

(combustion of hexane)

CH3COOC2H5 + 5 O2 –> 4 CO2 + 4 H2O

(combustion of ethyl acetate)

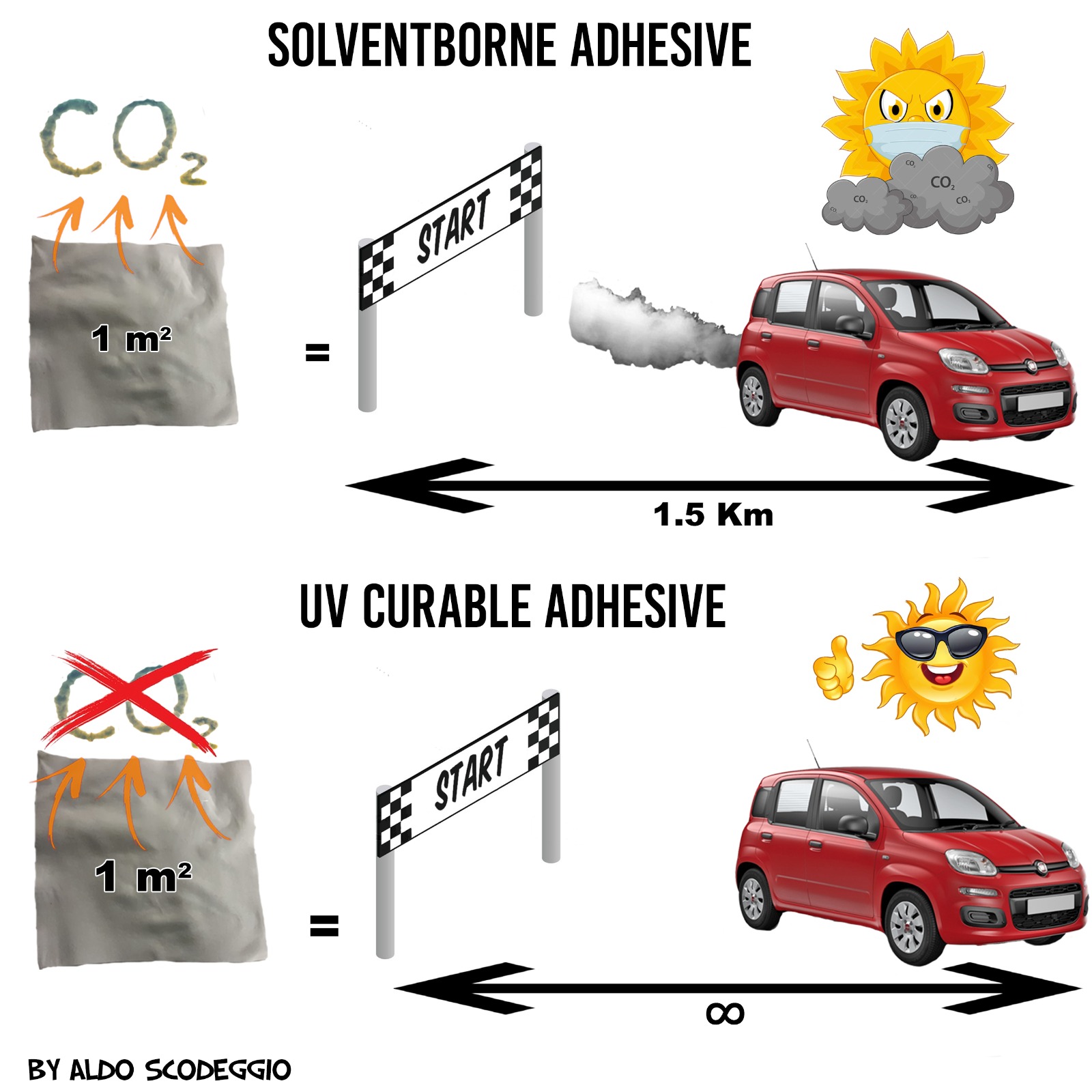

To quantify these formulas and assess how environmentally friendly UV adhesive production is, we compared two double-sided adhesives with similar characteristics made with the two different technologies, solvent vs. UV.

These were double-sided adhesives with TNT backing, total thickness 100 my.

A solvent/resin ratio of 50% was considered.

Of this 50% solvent, a hexane % of around 40% was assumed.

To obtain a weight of 50g per side, 100g wet of solvent would have to be coated. Of this 100g, 40g is hexane. This means that 120g of CO2 is released into the atmosphere for every square metre produced!

The same emission as a petrol-powered Panda 1.2 would produce to travel about 1.5 km!

The UV acrylic adhesive is 100% dry, hot-melt, spread and cross-linked with UV light.

No local CO2 emissions!

Considering that adhesive tape productions consist of tens of thousands of square metres, it is easy to see how much CO2 is avoided in the environment with ‘dry’ technology.

Today, Secad is one of the largest users of UV adhesives in Italy and plans to intensify its use further in the coming years.